Cabling

As part of the CRESST II readout system we required

cables to read out the SQUID sensors; supply the bias and heater signals

to the detectors; and connect the SQUIDs to the detectors. We achieved

this using woven cables supplied by Tekdata,

made to our design. The cables are designed to minimise the heat

load, while ensuring that crosstalk and susceptibility to external

electromagnetic interference remained very low. Some of the wires need to

have a low resistance, thereby presenting a significant heat load to the

helium main bath.

The woven cables consist of twisted wire pairs woven with an

insulating thread; the pairs are twisted in alternate directions

(clockwise or anticlockwise) and single wires (connected to ground) run

between them to reduce the crosstalk between channels. Inside the

cryostat the cables are clamped in heatsinks to ensure there is no

heatload on the detectors. The cables running inside evacuated tubes to

the top of the cryostat (at room temperature) are clamped inside baffles

to ensure a gradual reduction in the temperature, minimising the

heatload.

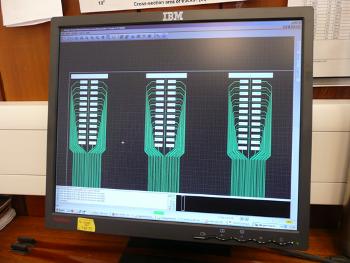

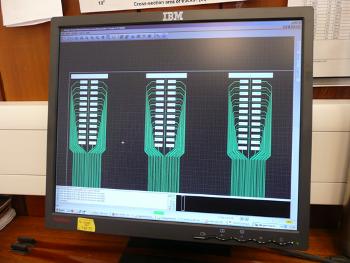

To compare the crosstalk in different cable designs, we developed

software to model the crosstalk between wires. The results, shown below,

confirm that our woven cable design was best. However due to the high

cost of supplying woven cables to readout the 1000+ detectors required

for

EURECA, we started investigating alternative

designs, such as Kapton cables - metals tracks

deposited on Kapton foil. In this case the design is even more critical

to ensure the crosstalk is kept within acceptable limits.

|

|

| Woven cable supplied by

Tekdata |

| |

|

| Kapton cable design |

|